With the development and utilization of gold resources, the world's easily leachable gold resources have been gradually exhausted, and the refractory gold deposits have gradually become the main development objects.

By conventional leaching method, the gold ore with leaching rate more than 90% is easy to leach, and the gold ore with leaching rate between 50% and 80% is difficult to leach.

The gold in refractory gold ores is usually wrapped in sulfide minerals in the form of fine particles. It is difficult to dissociate the gold monomer by the usual fine grinding (p80 = 53-75um). In the process of gold leaching, the leaching agent can not contact with gold, resulting in low recovery rate of gold and no economic value.

For the recovery and utilization of very fine-grained gold in refractory gold ores, it is found that ultra-fine grinding can destroy sulfide or mineral crystals on the right side of vein in physical level, thus exposing gold, thus effectively improving the recovery rate of fine-grained gold. When the ultra-fine grinding fineness of refractory gold ore is P80 = 8-12um, It can not only improve the kinetics of subsequent leaching, but also improve the thermodynamic reaction of leaching operation, reduce or eliminate the passivation of sulfide minerals on the surface of ore, improve the surface activation of gold ore, and effectively improve the leaching rate of cyanide leaching. In addition, ultra-fine grinding can also promote the reaction of trivalent iron and oxygen, and the fine-grained minerals after ultra-fine grinding have a large surface area, which is beneficial to improve the leaching rate of refractory gold ores and effectively reduce investment and operation costs.

With the rapid development of ultra-fine grinding technology and its successful application in mining industry, the industrial application of ultra-fine grinding technology in refractory low-grade gold ore can be realized. More and more refractory gold ore development process plans take ultra-fine grinding as pretreatment process of refractory gold ore or as a part of pretreatment process, in order to obtain greater and better economic benefits.

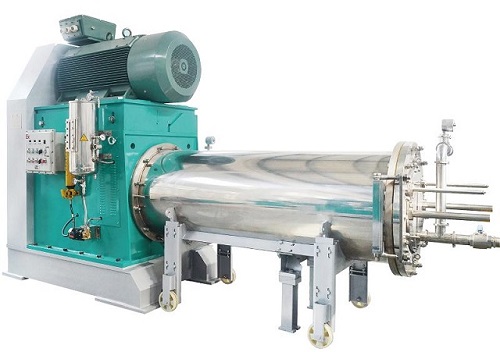

The main equipment used in ultra-fine grinding of gold ore is large flow horizontal sand mill, which integrates grinding and classification, and can grind gold flotation concentrate from 74um to 5-20um. After grinding, the gold concentrate pulp can be further oxidized and cyanidated, and the gold recovery can be increased from 30-40% to more than 90%.

Sinonine can offer a full range of gold superfine grinding machines and solutions. Using the large flow horizontal sand mill to grind the gold ore to be 5-20um.

Thank you for your interests in sinonine,if you want to buy our products, please fill in the form below and we will contact you immediately.